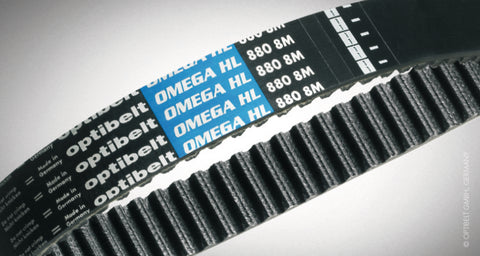

Optibelt OMEGA HL High-performance timing belts

If you are in need of drives with low belt speeds, the capacity of Optibelt OMEGA HL High-performance timing belts is up to 15% greater than that of optibelt OMEGA HP. The optibelt OMEGA HL was created with this in mind and is perfectly suited for shock-loaded drives as well as extreme fluctuating loads. The new drive designs are what is needed for this high-end application. The optibelt OMEGA HL can be used to deploy the highest level of functional reliability along with the highest level of effectiveness.

Timing belts made of optibelt OMEGA HL outperform optibelt OMEGA HP by up to 15% on drives with low belt speeds. Additionally, the design was improved to make the optibelt OMEGA HL much better suited for shock-loaded drives with highly variable loads. When used in these kinds of applications for new drive designs, optibelt OMEGA HL achieves the highest possible functional reliability in addition to the highest level of efficiency.

Feature of Optibelt OMEGA HL High-performance timing belts:

- Reinforced glass cord

- It requires no maintenance

- It is high resistance to shock loads

- It is highly dynamic and loadable

- It has a Very low stretch

- It has 15% additional power as compared to HP

- The Temperature range of OMEGA HL is -30°C to +100°C

- 8MHP and 14MHP profiles are electrically conductive.

Advantages of Optibelt OMEGA HL High-performance timing belts for HTD and RPP pulleys:

- Reinforced glass cord

- It requires no maintenance

- It is high resistance to shock loads

- It is high dynamical and loadable

- It has a very low stretch

- It offers Up to 15% more power compared to OMEGA HP

- The temperature range -30°C to +100°C

- Profiles 8MHP and 14MHP – Electrically conductive

Optibelt OMEGA HL High-performance timing belt is an ultra-high performance belt with a full range of speeds and extreme loads. For heavy industrial applications, strong fiberglass cords with aramid-blend fiber rubber cores are used. Fits standard HTD®, RPP®, and MR® pulleys, giving you increased performance and toughness without having to change out your current pulleys.

- Industrial Performance: Fiberglass cords with reinforcement offer exceptional strength and pulling power.

- Low noise: fabric cover and OMEGA tooth design for quieter operation.

- Toughness: The reinforced fabric cover offers greater wear resistance.

- Strength: The rubber compound is mixed with aramid fibers to create a tooth structure with incredible shear strength and low friction.

- It Fits HTD and RPP Pulleys. Versatility

- Increased operating temperature range: -22 to 212°F

- Anti-static: Complies with the requirements of ISO 9563.

The running noise level is significantly reduced by the Optibelt OMEGA tooth profile. The teeth are made to perfectly mesh with the pulley teeth with the least amount of friction. Timing belts made by Optibelt OMEGA operate in HTD and RPP pulleys. Shop Optibelt OMEGA HL High-performance timing belts, developed for heavily loaded, high-speed drives, from Bolton Engineering Products Ltd. Visit for more.

Leave a comment